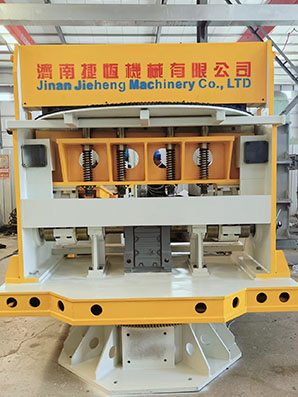

Swing shearing machine

he swing shearing machines produced by our company have the following advantages:

High dimensional precision:

Advanced control systems are adopted, which can precisely control the back gauge, shearing stroke, shearing angle and the clearance between the upper and lower cutting edges, ensuring high precision of the cutting dimensions.

High angular precision:

Through the cooperation of the precise mechanical structure and the control system, the sheet metal can be cut into various shapes such as rhombuses, parallelograms, trapezoids according to the set angles. With different cutting die configurations, it can also cut special shapes like arcs and waves.

In terms of cutting quality:

Good cut quality:

During the shearing process, as the tool holder makes a rotary motion, the shearing clearance and the shearing back angle of the swing shearing machine will change, making the force exerted by the cutting edge on the sheet metal more uniform during cutting, resulting in smoother and neater cuts without burrs or deformation.

Excellent surface quality:

The sheet metal runs continuously and smoothly, and the processing will not cause quality problems such as surface scratches or imprints.

In terms of work efficiency:

Fast shearing speed:

The movement mode of the tool holder of the swing shearing machine enables it to complete the cutting action quickly during the shearing process. For rectangular sheet materials, the maximum number of shearing times can reach 100 times per minute, and for non-rectangular sheet materials, the maximum number of shearing times can reach 60 times per minute.

High degree of automation:

Equipped with a numerical control system, it can realize multi-step programming functions, automatic continuous positioning of the back gauge, shearing base number functions, etc., reducing the manual operation time and labor intensity and improving production efficiency.

Structural Composition: Generally, it consists of parts such as the machine body, tool holder, transmission system, hydraulic system, control system, and back gauge device. The machine body usually adopts a steel plate welded structure, which has relatively high strength and rigidity. The tool holder is a key component that carries the cutting blades and completes the shearing action, and its design needs to meet the requirements of strength and precision. The transmission system includes motors, reducers, transmission shafts, etc., and is responsible for transmitting power to the tool holder. The hydraulic system provides the shearing force and the power for the return stroke of the tool holder, and it is composed of oil pumps, oil cylinders, valve groups, etc. The control system realizes the automatic control of the equipment and the adjustment of parameters. The back gauge device is used to position the sheet metal to ensure the precision of the shearing size.

Technical Parameters: They include the thickness of the sheet metal that can be sheared, the width of the sheet metal that can be sheared, the shearing angle, the number of strokes, the adjustment range of the back gauge, the power of the main motor, etc. For example, for the QC12Y hydraulic swing shearing machine, the thickness of the sheet metal that can be sheared ranges from 4 mm to 25 mm, the width of the sheet metal that can be sheared ranges from 2,500 mm to 5,000 mm, the shearing angle is generally between 1°30′ and 3°, the number of strokes varies according to the thickness of the sheet metal, and the adjustment range of the back gauge is relatively wide.

Control System: Commonly used ones include the DAC360/DAC362S control system of the Dutch company Delem. It can precisely control the position of the back gauge, the shearing stroke, the shearing angle and the clearance between the upper and lower cutting edges, realize the automatic adjustment of the shearing stroke, improve production efficiency and shearing precision. It also has a high-speed and long-stroke back gauge with linear guides and ball screw transmission, with a speed that can reach 250 mm/s and a back gauge stroke that can reach 1,000 mm.

Equipment Applications

Metal Processing Industry: It is widely used in the processing of various metal sheets, such as carbon steel, aluminum sheets, stainless steel, etc. It can cut the sheets into the required sizes and shapes for manufacturing mechanical parts, automobile parts, ship components, building steel structures, etc.

Electronics and Electrical Appliances Industry: It is used to cut the thin metal sheets required for parts such as the casings of electronic equipment and circuit boards, such as computer cases, mobile phone casings, TV back panels, etc., meeting the requirements for the precision and quality of the sheets.

Power Equipment Industry: It can process metal parts in power equipment such as transformers and distribution cabinets, such as the shearing of silicon steel sheets, ensuring that their dimensional precision and shapes meet the design requirements and improving the performance and quality of power equipment.

Pipeline Processing Industry: In pipeline manufacturing, it is used to cut the sheets required for pipelines, such as cutting steel plates into circular, square and other shapes to make pipeline elbows, tees, flanges and other components.

Decoration and Renovation Industry: It is used to cut decorative materials such as stainless steel sheets and aluminum sheets to make decorative components such as doors, windows, curtain walls, railings, and suspended ceilings, meeting the requirements of different decoration styles and design requirements.

Our company's main products include: uncoiling, leveling and transverse shearing lines, uncoiling, longitudinal shearing and winding lines, flying shearing lines, uncoiling and swing shearing production lines, belt tensioners, uncoiling, pressure blanking lines, high-speed feeding and laser blanking lines, etc. The production period is short, the efficiency is high, and the delivery is fast. We can provide you with technical solutions for free. Welcome to consult.

Submitted successfully

We will contact you as soon as possible