Slitting and winding line

Uncoiling Section

It includes an uncoiler, an uncoiling tension device, etc. The uncoiler is responsible for unwinding the metal coil, while the uncoiling tension device controls the tension of the coil during the uncoiling process to ensure that the coil is unwound smoothly.

Slitting Section

The core component is the circular shear. It longitudinally shears the coil through multiple sets of circular blades, cutting the wide coil into narrow strips with the required widths. It also includes guide and guard devices, clamping devices, etc., which are used to guide the coil and fix its position to ensure the cutting precision.

Winding Section

It consists of a winder, a constant tension winding device, etc. The winder rewinds the narrow strips of the coil after slitting into rolls. The constant tension winding device can make the coil subject to uniform and stable tension during the winding process, avoiding situations such as looseness and wrinkling of the coil.

Auxiliary Devices

For example, the loop accumulator can store a certain amount of coil during the shearing process, playing a role in buffering and adjusting the tension. The scrap chopper is used to chop the waste edges generated during longitudinal shearing for convenient recycling. Besides, there are also liner paper devices, scrap carts, discharge trolleys, and so on.

Workflow

Technical Parameters

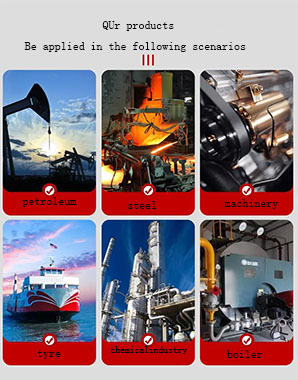

Application Fields

It is mainly applicable to industries such as transformers, motors, home appliances, automobiles, building materials, packaging, etc., providing high-precision and high-quality metal narrow strip coils for these industries.

Submitted successfully

We will contact you as soon as possible