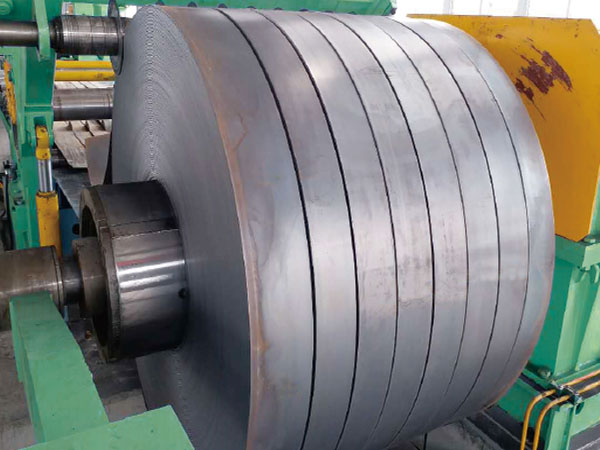

Large Slitting Line

The advantages of longitudinal cutting production lines.High degree of automation: Most longitudinal cutting production lines adopt automated control systems to reduce labor costs and improve production efficiency. Improve product quality: By cutting on the longitudinal cutting production line, the quality of the product can be effectively controlled to ensure that it meets standard requirements. Environmental protection and energy conservation: The longitudinal cutting production line adopts modern equipment and technology, which can reduce waste and energy consumption, and meet environmental protection requirements.

A longitudinal cutting production line is an equipment used to cut large coils into the required width, mainly used in industries such as metal materials and plastic films. Its working principle is as follows:

1. Unwinding: First, the large rolls of raw materials are transported to the slitting machine through the coil conveying system.

2. Tensioning: Tighten the roll material to ensure that there is no looseness during cutting.

3. Cutting: The coil is longitudinally cut by a cutter, and the cut small coil will continue to be transported to the next process.

4. Roll up: The cut small rolls are sorted and rolled up through a roll up device.

5. Output: After sorting the small rolls, they are output through the conveying device to complete the entire production line.

Submitted successfully

We will contact you as soon as possible