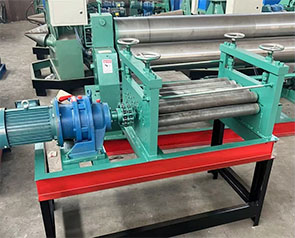

steel plate straightening machine

The steel plate straightening machine offers a range of advantages that contribute to improved productivity, efficiency, and quality in steel plate processing.

Firstly, one of the key advantages of the steel plate straightening machine is its ability to provide precise and accurate straightening of steel plates. This ensures that the final product meets the required specifications and standards, leading to high-quality end products.

Moreover, the machine helps to minimize warping and distortion in steel plates, resulting in a more uniform and flat surface. This is crucial for applications where flatness and consistency are critical, such as in the manufacturing of automotive parts, machinery components, and construction materials.

Another important advantage is the increased productivity and cost savings that the machine offers. By automating the straightening process, the machine reduces the need for manual labor and speeds up production times. This not only boosts efficiency but also leads to cost reductions for companies in terms of labor expenses and production downtime.

Furthermore, the steel plate straightening machine enhances workplace safety by reducing the risk of injuries associated with manual handling of heavy steel plates. The automated operation of the machine minimizes the need for physical exertion by operators, thus creating a safer working environment.

Additionally, the machine's versatility allows it to handle a wide range of steel plate sizes and thicknesses, making it suitable for various industrial applications. This flexibility is advantageous for companies that work with diverse steel plate dimensions and materials.

In conclusion, the steel plate straightening machine presents a multitude of benefits, including improved precision, reduced warping, enhanced productivity, increased safety, and versatility in steel plate processing. Its capabilities make it a valuable asset for industries that require high-quality, flat steel plates for their operations.

I. Excellent leveling effect

High-precision correction

It can achieve high-precision leveling of steel plates and control the flatness error within a very small range. For example, in some industries with extremely high flatness requirements, such as automobile manufacturing and precision instrument production, the steel plate leveling machine can ensure that the flatness error of each square meter of steel plate does not exceed ±0.5 millimeters, providing a solid foundation for subsequent processing and use.

By adopting advanced leveling technology and precise roll system design, after the steel plate is processed by the leveling machine, the surface flatness is uniform. Whether in local areas or the entire plate surface, it can meet high-standard flatness requirements.

Effective stress elimination

During the leveling process, it can not only correct the shape deformation of the steel plate but also effectively eliminate the residual stress inside the steel plate through reasonable pressure distribution and roll system movement. This is of great significance for improving the quality and performance of steel plates and can prevent deformation, cracking and other problems of steel plates due to stress concentration during subsequent use.

For example, in the processing of steel plates for building structures, the structural stability and bearing capacity of the steel plates after stress elimination treatment by the leveling machine are significantly improved, enabling them to better adapt to various complex building environments and stress conditions.

II. Efficient production capacity

Fast leveling speed

It has a relatively high leveling speed and can process a large amount of steel plates in a short time. According to different models and steel plate thicknesses, the leveling speed can reach several meters or even dozens of meters per minute. For enterprises with large-scale production, this greatly improves production efficiency and shortens the production cycle.

For example, in some large steel structure manufacturing enterprises, an efficient steel plate leveling machine can quickly level the raw material steel plates to meet the continuous operation needs of the production line, thereby improving the efficiency of the entire production process.

Continuous operation performance

The design focuses on the stability and reliability of continuous operation and can run continuously for a long time. It adopts high-quality materials and advanced manufacturing processes to ensure that key components such as leveling rolls and transmission systems can still maintain good performance under long-term high-load work.

At the same time, it is equipped with a perfect cooling and lubrication system, which effectively reduces wear and heat generation during equipment operation, further extends the service life of the equipment, and guarantees the continuity of production.

III. Wide applicability

Adapt to various steel plate materials

It can be applied to various steel plates of different materials, including ordinary carbon steel, alloy steel, stainless steel, etc. Whether it is alloy steel with high hardness or stainless steel plate with special properties, the steel plate leveling machine can perform effective leveling treatment according to its material characteristics.

For steel plates of different materials, the equipment can adjust leveling parameters such as pressure, roll spacing, and leveling speed to achieve the best leveling effect and meet the processing needs of different industries for steel plates of different materials.

Handle different thickness specifications

It has a wide thickness processing range and can handle thin plates as thin as a few millimeters to medium and thick plates as thick as dozens of millimeters or even thicker. Whether it is a thin plate used for manufacturing electronic product casings or a thick plate used for large mechanical equipment, the steel plate leveling machine can provide an appropriate leveling solution.

By flexibly adjusting the roll system configuration and working parameters of the equipment, it can accurately adapt to the leveling requirements of steel plates of different thicknesses and ensure good leveling quality under various thickness specifications.

IV. Reliable quality and stability

Sturdy and durable structure

The fuselage is made of high-strength metal materials, such as high-quality steel welded, and has strong rigidity and stability. The frame structure is reasonably designed and can withstand the huge pressure and impact force generated during the leveling process, and is not easily deformed and damaged.

Key components such as leveling rolls are made of high-quality alloy steel. After precision processing and heat treatment, they have good wear resistance and fatigue resistance, ensuring the reliability and stability of the equipment during long-term use.

Advanced control system

Equipped with an intelligent control system, it can achieve precise control of the leveling process. Through the operation interface such as a touch screen, the operator can easily set and adjust various parameters such as leveling speed, pressure, and roll spacing.

The control system also has automatic detection and fault diagnosis functions, which can monitor the running status of the equipment in real time and find and solve potential problems in time. For example, when an abnormal pressure of a leveling roll is detected, the system will automatically alarm and take corresponding protection measures to avoid equipment damage and production accidents.

V. Energy saving and environmental protection

Optimized energy utilization

Adopt advanced energy-saving technology and optimize the design in aspects such as motor drive and transmission system to improve energy utilization efficiency. For example, a motor with frequency conversion speed regulation technology can automatically adjust the speed and power according to the actual leveling needs of steel plates, avoiding energy waste.

During the leveling process, through reasonable pressure control and roll system movement planning, the equipment can minimize energy consumption while ensuring the leveling effect. Compared with traditional leveling equipment, it can save energy by about 10% - 20%.

Reduce waste generation

The high-precision leveling ability reduces waste generation caused by unqualified leveling. By precisely controlling the leveling process, the flatness of the steel plate can be adjusted to the required standard at one time, avoiding material loss caused by repeated leveling or excessive leveling.

This is of great significance for saving resources and reducing production costs, and also conforms to the development concept of modern industrial green environmental protection.

VI. Convenient operation and maintenance

User-friendly operation interface

A simple, understandable, and user-friendly operation interface is designed. Operators can master the operation method of the equipment proficiently after simple training. The operation interface displays various key parameters and running status information, which is convenient for operators to monitor and adjust in real time.

At the same time, the equipment is also equipped with some intelligent operation functions, such as automatic feeding and discharging control, which further reduces the labor intensity of operators and improves work efficiency.

Easy to maintain

The structure is designed reasonably, which is convenient for daily maintenance and upkeep of the equipment. For example, key components such as leveling rolls adopt a structure that is easy to disassemble and install, which is convenient for regular inspection, maintenance, and replacement.

The equipment is also equipped with a perfect lubrication system and protective device, which reduces the wear and damage of components and extends the service life of the equipment. At the same time, detailed maintenance manuals and technical support are provided to provide strong guarantee for users' maintenance work.

Submitted successfully

We will contact you as soon as possible