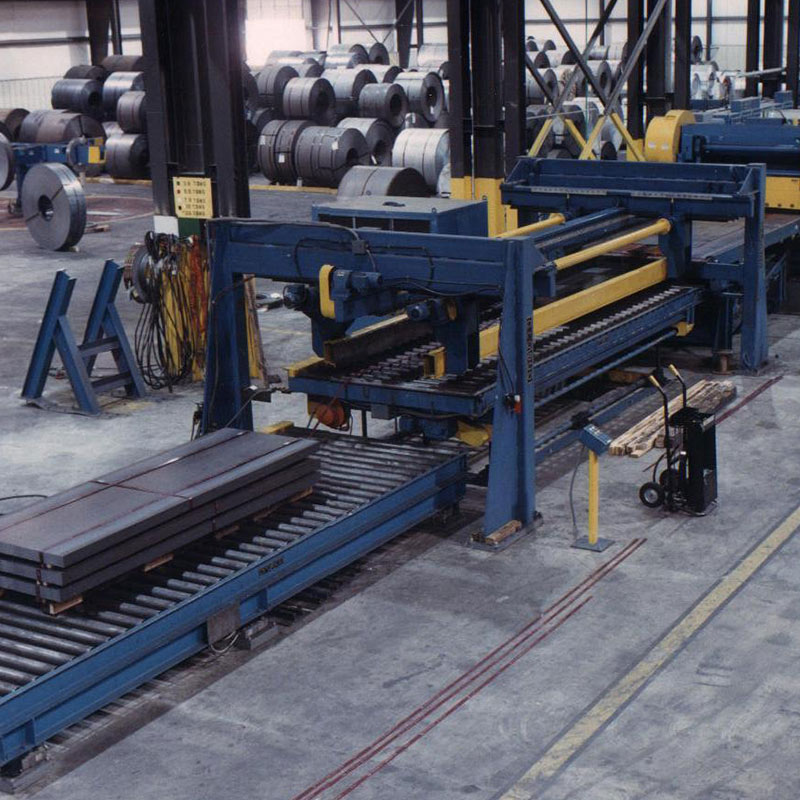

Cold Rolled Stainless Steel Cut to Length Machine Line

Processing Material:Cold/Hot Rolled,Galvanized,Stainless,Carbon Steel

Processing Thickness: 3-12mm

Processing Width: 900-2000mm

Cutting Accuracy: ±1.5mm

Max. Speed: 30m/Min

Max. Cutting Frequency:15spm

Product Description:

Cut to size line ECL series

A reduce to size line is normally used for jobs like uncoiling, straightening, measuring, cross-cutting to size and stacking of a number substances such as bloodless or warm rolling carbon steel, tinplate, stainless steel, and different types of metallic with lined surfaces.

Features of Cut to Length Line:

1. Our reduce to size line makes use of a roll feeding, AC servo drive.

2. It has a entirely digital size manage gadget that ensures quickly positioning with little error.

3. It has a tough chrome plated floor and is long lasting and abrasion resistant.

4. It is used collectively with a hydraulic shear or an air-clutch shear to elevate out speedy shearing and handy clearance adjustment.

5. Our reduce to size line is appropriate for warm rolling carbon steel, tinplate, stainless steel, and different sorts of metals with covered surfaces.

Advantage:

1. High diploma of automation, convenient & dependable operation

2. High size precision, excessive sheet flatness

3. Good order stacking

Basic Info.

Model NO. | ECL-12X2000 |

Certificate | CE, ISO9001 |

Automation | Yes |

Specification | CE, ISO9001 |

Origin | Jinan, Shangdong |

Production Capacity | 60 Sets/Year |

Uncoiling Weight | 35t |

| 12 Months |

Transport Package |

|

Uncoiling Weight |

|

Trademark | Eagle |

HS Code | 8462312000 |

Basic Info.

Model NO. | ECL-12X2000 |

Cutting Accuracy | ±0.5mm |

Max. Cutting Frequency | 40spm |

Certificate | CE, ISO9001 |

Transport Package | Seaworthy |

Trademark | Eagle |

HS Code | 8462312000 |

Processing Width | 900-1850mm |

Max. Speed | 50m/Min |

Uncoiling Weight |

|

Guarantee Period | 12 Months |

Specification | CE, ISO9001 |

Origin | Jinan, Shangdong |

Production Capacity | 60 Sets/Year |

ECL series cut to length line is composed of the followings:

1 | Entry coil car | 1 set |

2 | 1 set | |

3 | Outboard support | 1 set |

4 | Feeding table | 1 set |

5 | Leveler | 1 set |

6 | Loop table | 1 set |

7 | Side guide | 1 set |

8 | Servo feed roll | 2 pairs |

9 | Shear | 1 set |

10 | Conveyor belt | 1 set |

11 | Stacker | 1 set |

12 | Blower | 1 set |

13 | Hydraulics | 1 set |

14 | Electrics | 1 set |

Uncoiling Unit

This uncoiling unit of our reduce to size line lets in countless coil shares to be pre-placed on the loading station. It is reachable with single head or double heads to swimsuit exclusive requirements.

Leveler

The leveler of our reduce to size line may additionally have a range of designs, from 2H, 4H or 6H. It can be flexibly managed and can elevate out desirable leveling of the plate materials. Its leveling roll is made of roll metal with a chrome-plated surface. It is of excellent abrasion resistance and lengthy carrier life.

Feeder and Shear

Our reduce to size line employs a pair or two pairs of feed rolls, pushed by using an AC servo motor, to feed the strip to the set size precisely. They make sure quickly positioning with little error. These feed rolls are well suited with a hydraulic shear or an air-clutch shear to lift out speedy shearing and handy clearance adjustment. It can be outfitted with a roll kind or a belt kind conveyor.

Stacking Unit

Our reduce to size line can be outfitted with a pneumatic or electromagnetic stacking unit. It is geared up with a blower to guard the floor from scraping. Both longitudinal and transverse stacking are available.

Besides,there are additionally different sorts of ECL sequence reduce to size lines,all the reduce to size line are sa follows:

Model | Coil thickness(mm) | Coil width(mm) | cut tolerance(mm) | Line speed(max)(m/min) | Shear number(max)(spm) | Coil weight(ton) |

ECL-2X1300 | 0.2-2 | 300-1300 | ±0.3 | 60 | 50 | 7/15 |

ECL-2X1600 | 0.2-2 | 400-1600 | ±0.3 | 60 | 50 | 7/15 |

ECL-2X1850 | 0.2-2 | 900-1850 | ±0.3 | 50 | 40 | 20 |

ECL-3X1600 | 0.5-3 | 400-1600 | ±0.3 | 50 | 40 | 15 |

ECL-3X1850 | 0.5-3 | 900-1850 | ±0.3 | 50 | 40 | 20 |

ECL3X2000 | 0.5-3 | 900-2000 | ±0.3 | 45 | 40 | 30 |

ECL-6X200 | 1-6 | 600-1600 | ±1 | 25 | 20 | 20 |

ECL-6X1600 | 1-6 | 900-2000 | ±1 | 25 | 20 | 30 |

ECL-8X2000 | 2-8 | 900-2000 | ±1 | 20 | 20 | 30 |

ECL-12X2000 | 3-12 | 900-2000 | ±1.5 | 20 | 10 | 30 |

ECL-16X2000 | 4-16 | 900-2000 | ±2 | 15 | 8 | 30 |

Transaction procedure:

Inquiry - Project - Sign - Production - Inspection - Payment - Transportation - Installation& Commissioning - Guaranty

Jinan Jieheng Machinery Co., Ltd. was once registered in September 2017 and is positioned at No. 10-1, Xiaolizhuang Industrial Park, Huaiyin District, Jinan City, Shandong Province.

The business enterprise covers an location of 15 acres and has constructed a workshop of greater than 5,860 rectangular metres. There are extra than 50 employees, of which extra than 60% are engaged in the unwinding line, specialising in the manufacture, lookup and development, sales, installation, preservation and technical provider of CNC automation equipment, ordinary equipment, electrical equipment, CNC desktop tools, hydraulic and pneumatic equipment, and so on. The organization is relying on its very own advantages, wholly relying on the Jinan Foundry and Forging Machinery Research Institute (state-owned enterprises) of the science and administration and different resources, attaching significance to the introduction and cultivation of management, advertising and technical personnel, the integration of exterior resources, optimise the inside management, and proceed to advance and innovate, and stride ahead in the route of commercial enterprise specialization and diversification of operations.

Submitted successfully

We will contact you as soon as possible